- screwdriver

- a pointed tool like an awl

- goatee

- hammer

Remove the spark torque sensor from the vehicle (see subsection 8.4.3.).

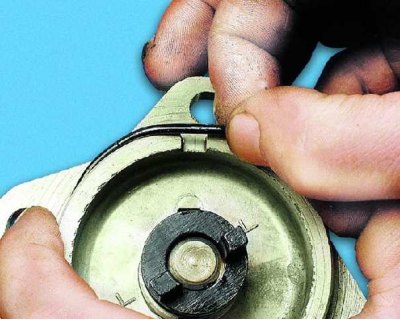

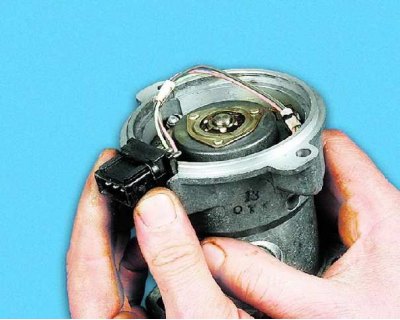

1. Carefully, without using any sharp metal tool, remove the sealing rubber ring from the outer groove of the spark torque sensor housing.

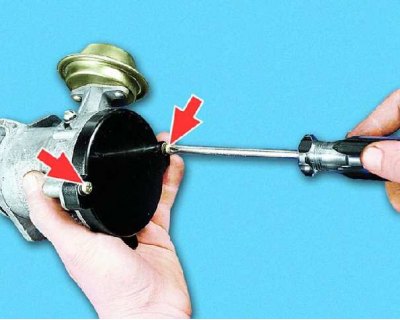

2. Remove the sensor cover by unscrewing the two screws securing it.

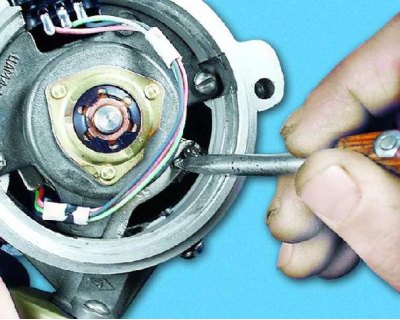

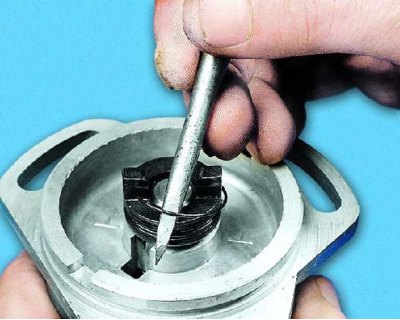

3. Remove the spring retainer of the vacuum regulator rod with an awl.

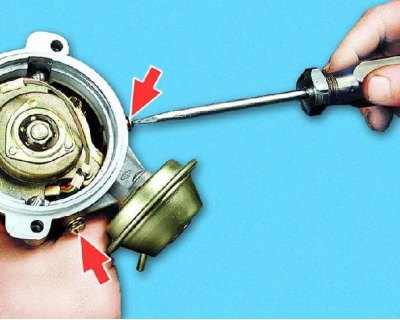

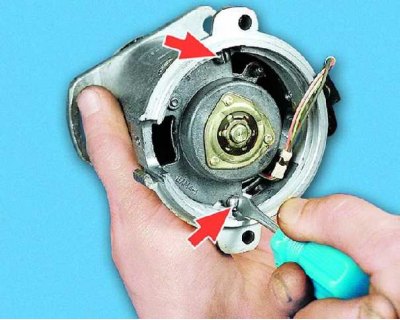

4. Remove the two screws securing the vacuum regulator and...

5.... after disconnecting its rod from the pin of the sensor base plate, remove the regulator.

6. Remove the screw securing the connecting block of the wiring harness of the Hall sensor and...

7.... by moving the block up, remove it from the spark torque sensor housing.

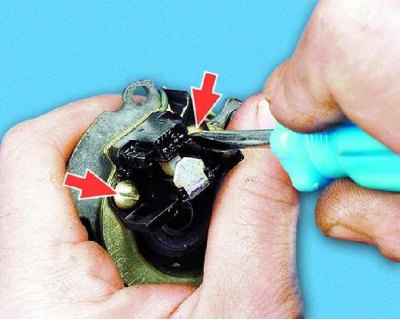

8. Turn out two screws of fastening of the holder of the forward bearing of the roller and...

9....remove the holder together with the Hall sensor and base plate.

10. Remove the two screws securing the Hall sensor to the base plate and...

11.... remove the sensor from it.

12. Remove the two screws securing the base plate to the front bearing holder and...

13....remove these screws, being careful not to lose the locking plates underneath.

14. Insert two flat screwdrivers into the gap between the base plate and the front roller bearing holder and use them to remove the base plate from the bearing seat...

15....together with the bearing.

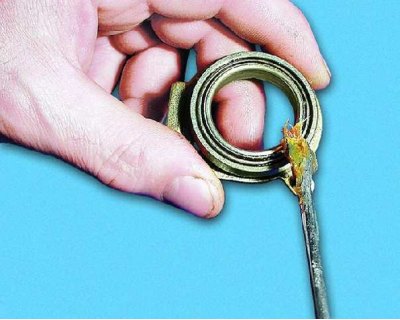

16. sharpened tool (awl) pry and remove the free end of the coil spring from the groove of the coupling and...

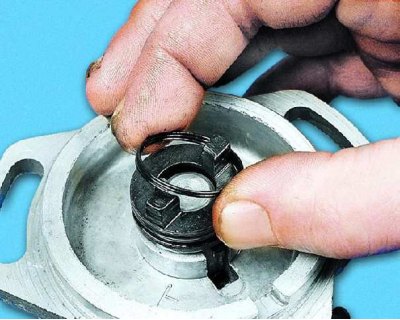

17.... remove the spring.

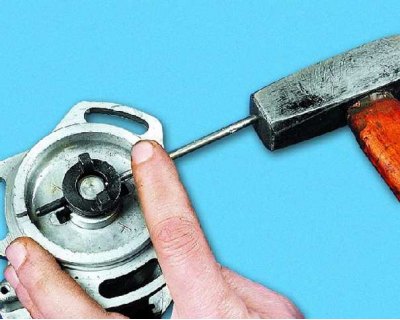

18. With light blows of a hammer through a beard of a suitable size, knock out the fixing pin from the holes of the coupling and the roller.

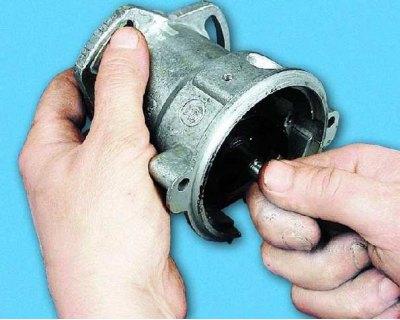

19. Remove the pin through one of the grooves in the end of the spark torque sensor housing and...

20.... remove the clutch from the roller.

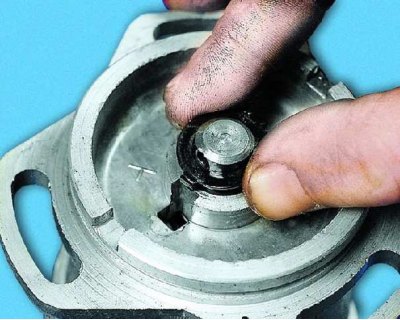

21. Remove the set of spacers from the roller and...

22.... shaped thrust washer.

23. Remove the roller with the centrifugal regulator and washers from the spark torque sensor housing.

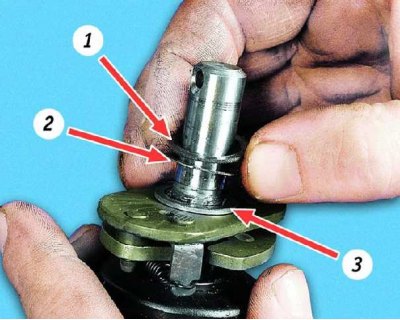

24. Remove textolite antifriction 1, steel adjusting 2 from the shaft shank (thin) and stubborn 3 (thick) washers.

25. Inspect the removed spark torque sensor housing O-ring. Replace a severely deformed, torn ring.

26. Check the removed vacuum regulator by pushing its rod into the housing until it stops...

27....tightly close the vacuum connection with your finger and release the pull. The rod should remain in a recessed position, and when the fitting is opened, it should sharply move forward. If the rod does not hold in the recessed position or does not extend clearly, the regulator is defective, replace it.

28. Carefully inspect the backplate bearing for lubrication and ease of rotation. If necessary, flush the bearing with gasoline and fill the gaps between the balls with fresh grease.

29. If the bearing is seizing or has axial and radial play, replace the shim and retainer assembly with the bearing.

30. Check the ease of movement of the weights of the centrifugal regulator and the regulator itself on the roller. If parts are stuck, flush the assembly with gasoline or kerosene and lubricate the moving joints with grease. Check that the Hall sensor screen is securely attached to the roller. Even with a slight play in the connection, replace the roller assembly with the screen.

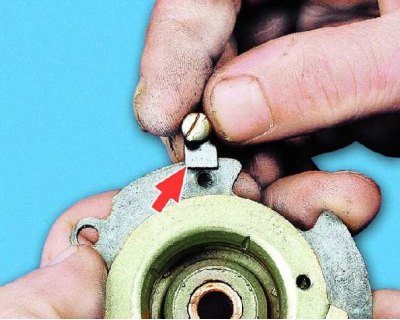

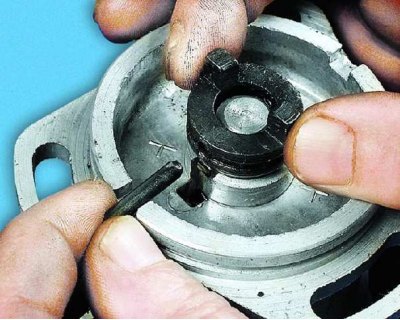

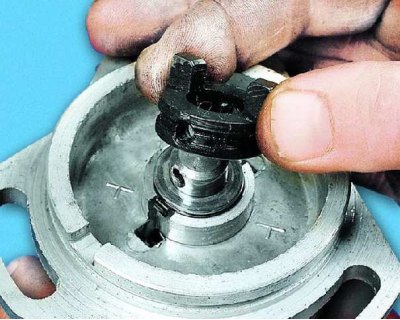

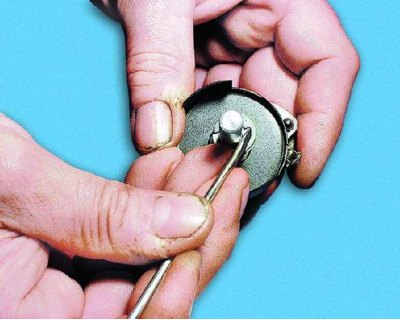

31. To remove the screen, use a screwdriver to remove the lock washer...

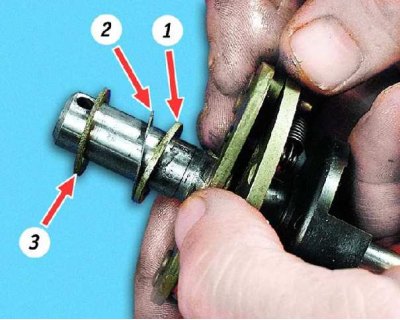

32....remote washer (if it is installed)...

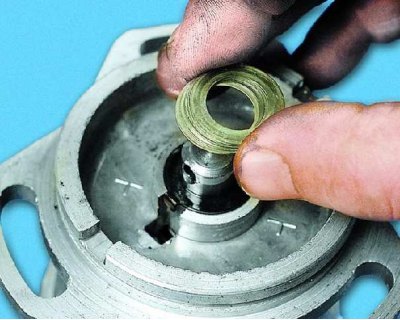

33.... with a pointed tool, unhook the ends of the springs from the holders of the regulator base (a small spring is hooked on a holder marked with paint; if the springs are incorrectly installed, the regulator setting will change) And...

34....remove the screen from the roller.

35. Remove the springs from the shield pins. Note that the large spring is hooked onto the extended pin.

36. Reassemble the spark torque sensor in the reverse order of disassembly, lubricating all friction surfaces with a thin layer of grease. Roller axial play (no more than 0.35 mm) provide with the selection of shims 2 installed between the thrust 1 and anti-friction 3 washers.