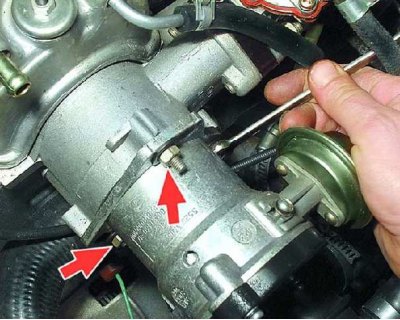

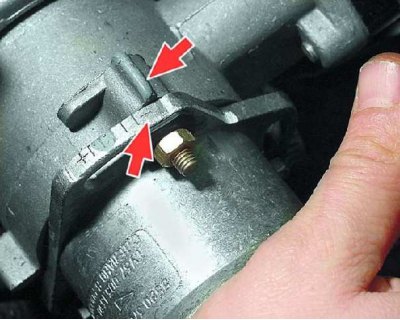

Location of spark torque sensor: 1 – sparking torque sensor; 2 - vacuum regulator; 3 - hatch cover in the clutch housing; 4 – the case of a drive of auxiliary units of the engine

You will need:

- key "on 10"

- stroboscope (device for checking and setting the ignition timing of carburetor engines)

Before you start: Remove the air filter.

The ignition timing is checked and set at idle speed of the engine (at a crankshaft speed of 820–900 min–1). The angle must be within 1°±1°before TDC.

If the ignition timing is set incorrectly, the engine overheats, does not develop full power, and detonation occurs.

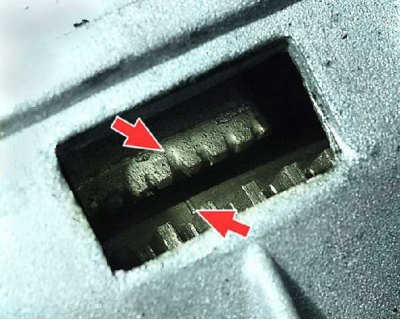

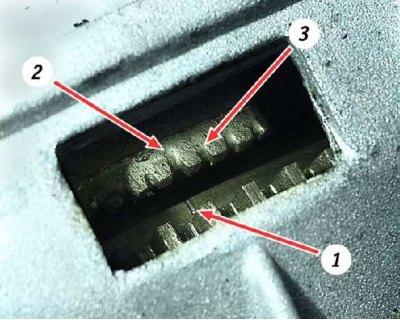

Tags for checking the ignition timing

Check the ignition timing according to the risk on the flywheel and the scale of the holder of the rear oil seal of the crankshaft (rubber plug removed). When combining the risks on the flywheel with the average division (neckline) On the scale, the piston of the first cylinder is set to TDC. One division on the scale corresponds to 2°of rotation of the crankshaft.

The ignition timing can also be checked and set according to the marks on the alternator drive pulley and the front cover of the camshaft drive belt. The long mark corresponds to the installation of the first cylinder at TDC, the short mark corresponds to the ignition advance by 5°of the crankshaft rotation. These marks set the moment of ignition on the stand.

1. Disconnect the hose from the vacuum regulator.

2. To check the ignition timing, connect the clamp " " stroboscope to terminal " " battery, and...

3.... clamp "masses" stroboscope - to the terminal "–" battery.

4. Remove the tip of the high-voltage wire from the spark plug of the first cylinder and connect it to the strobe sensor in accordance with the instructions that came with the strobe.

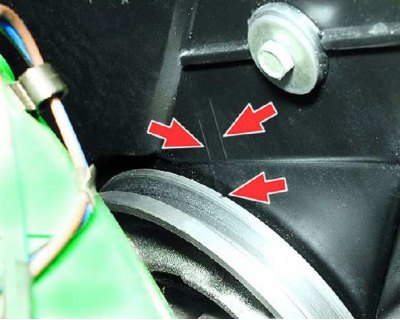

5. Remove the rubber plug from the clutch housing hatch.

6. Start the engine and direct the flashing strobe light into the clutch housing hatch.

7. When the ignition timing is correctly set, mark 1 on the flywheel should be between the middle division 2 and the previous division 3 of the scale. Otherwise, the ignition timing must be adjusted.

8. To set the ignition timing, loosen the three nuts securing the spark torque sensor.

9. To increase the ignition timing, turn the sensor housing clockwise (label " " on the flange of the sensor housing to the lug on the accessory drive housing. In this case, one division on the flange corresponds to 8°rotation of the crankshaft).

10. To decrease the ignition timing, turn the sensor housing counterclockwise (label "-" on the sensor housing flange to the lug on the accessory drive housing). Tighten the sensor mounting nuts, check and, if necessary, repeat the ignition timing setting. Connect the hose to the vacuum regulator.