You will need:

- keys "for 8", "on 10", "at 13", "at 17" And "at 19"

- interchangeable heads "on 10", "at 13", "at 17" And "at 19"

- keys for bolts with an internal hexagon "by 5" And "on 10"

- knob

- pliers

- screwdriver

- flat feeler set

- micrometers (with measurement limits 0-25, 25-50 and 75-100 mm)

- caliper

- dial gauge with indicator stand

- torque wrench

- oil filter remover

Remove the power unit from the car and the gearbox from the engine (see subsection 10.6.).

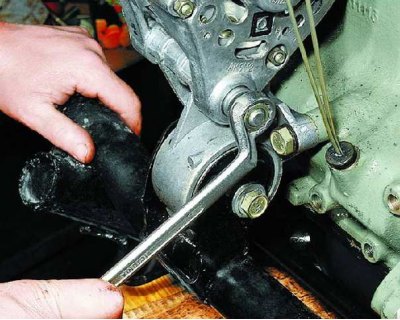

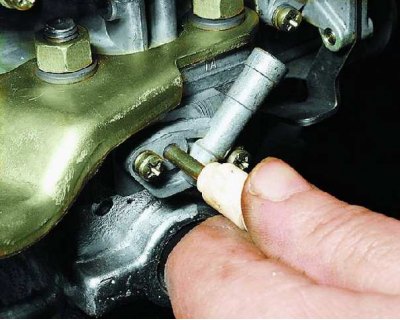

1. Unscrew the nut of the bolt of the lower fastening of the generator to the front engine mount and...

2.... remove the spring and flat washers from the bolt.

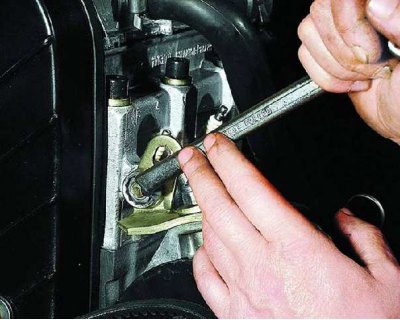

3. Loosen the nut securing the alternator to the tension bar.

4. Loosen the nut securing the alternator tension bar to the cylinder head stud.

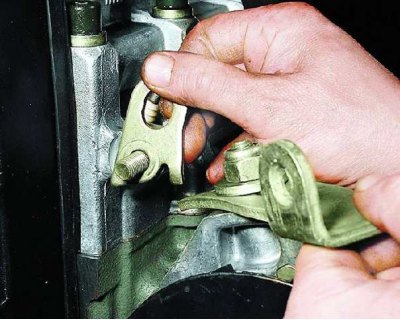

5. Remove the eye from the stud and the tension bar. Install the eye on the stud and screw on the nut (eye will be needed to remove the engine from the subframe).

6. Remove the alternator drive belt from the alternator pulleys and the engine crankshaft.

7. Take out a bolt of the lower fastening of the generator to a forward support of the engine and remove the generator together with a tension level.

8. Remove the oil dipstick from the bore of the cylinder block.

9. Loosen the crankcase ventilation hose clamps and remove the hose.

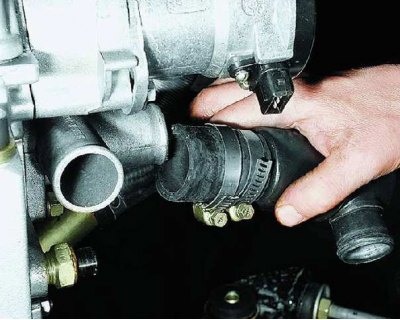

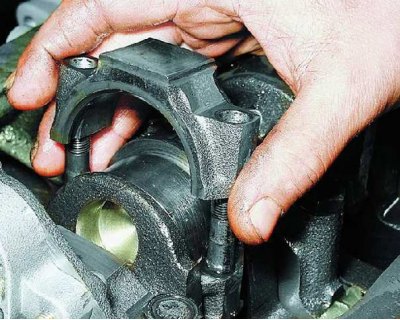

10. Loosen the clamp of the connecting hose on the outlet pipe of the cylinder head and...

11.... remove the hose from the nozzle together with the thermostat.

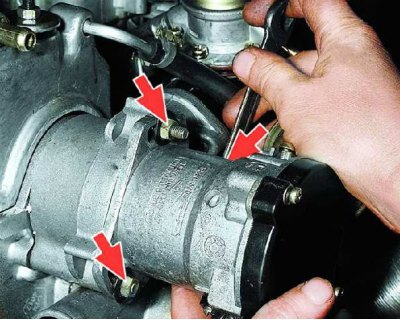

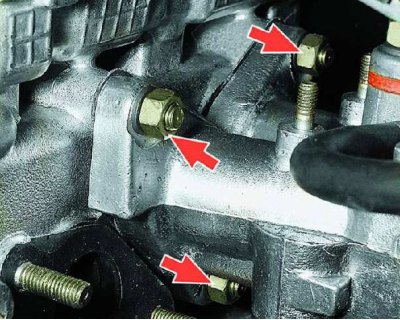

12. Remove the three nuts securing the spark torque sensor to the accessory drive housing.

13. Disconnect the hose from the vacuum ignition timing controller and remove the spark torque sensor from the drive housing.

14. Loosen the clamps and disconnect the vacuum booster hoses from the intake pipe and...

15.... inlet pipe heating.

16. Loosen the clamp and disconnect the crankcase ventilation small branch hose from the cylinder head cover fitting.

17. Loosen the fuel hose clamp (from fuel pump to carburetor) And...

18.... remove it from the injection fitting of the fuel pump.

19. Loosen the two fuel pump nuts and...

20.... remove the fuel pump from the drive housing studs.

21. Loosen the bolt securing the accessory drive housing and...

22.... remove the drive housing from the cylinder head studs.

23. Remove the two bolts securing the exhaust pipe bracket (spring washers are installed under the bolts).

24. Unscrew the four nuts securing the muffler exhaust pipe flanges to the cylinder head studs (flat washers installed under the nuts) And...

25.... remove the intake pipe with the bracket and the hose for supplying warm air to the air filter.

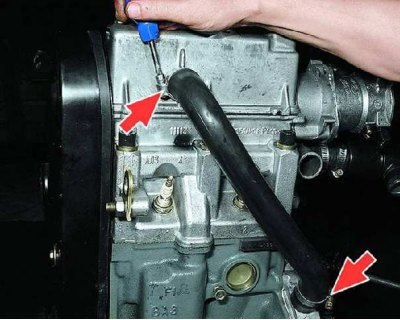

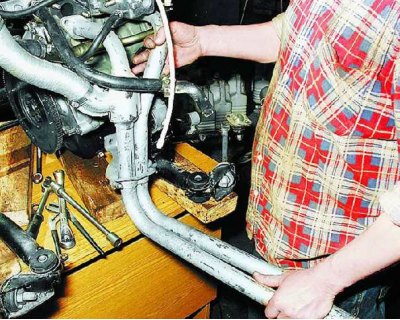

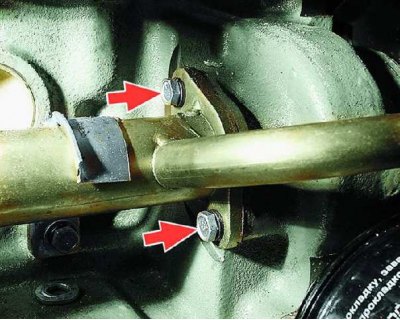

26. Remove the two bolts securing the flange of the water pump inlet pipe.

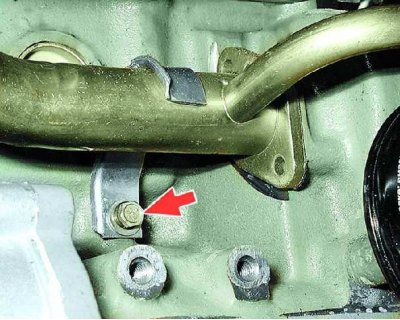

27. Loosen the bolt securing the inlet pipe bracket to the cylinder block and...

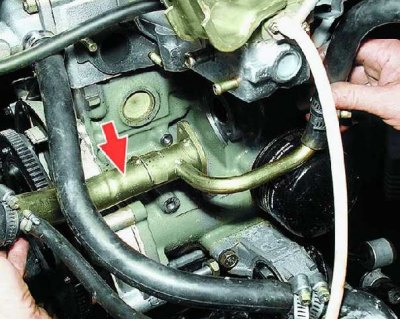

28.... remove the water pump inlet pipe with hoses and thermostat assembly.

29. Loosen the clamp and remove the heater outlet hose from the cylinder head outlet pipe.

30. Disconnect the vacuum ignition timing regulator hose from the carburetor fitting.

31. Remove the three nuts securing the intake pipe to the cylinder head (flat washers installed under the nuts) And...

32.... remove the intake pipe assembly with the carburetor.

33. Attach hoist straps to engine frames. Raise the engine by tightening the straps. Loosen the nut of the bolt securing the front engine mount to the subframe bracket...

34....remove the spring and flat washers and...

35....remove the bolt with flat washer.

36. Unscrew the nut of the bolt securing the rear engine mount to the subframe, remove the spring and flat washers and...

37....remove the bolt with flat washer. Remove the engine from the subframe.

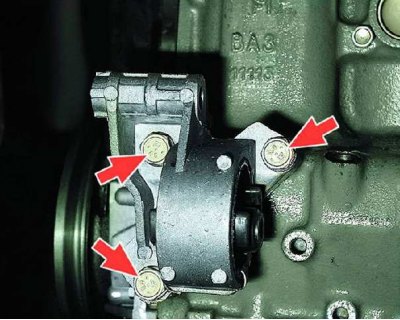

38. Place the engine on a stable stand or stand for disassembly and reassembly. Turn away three bolts of fastening of a forward support of the engine to the block of cylinders and remove a support.

39. Remove the oil filter from the engine (we recommend using a special puller).

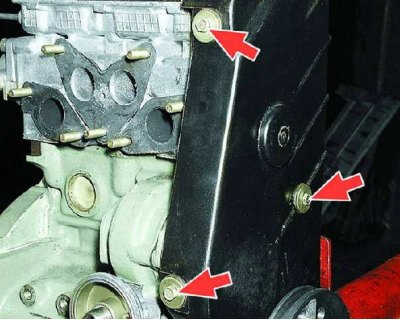

40. Remove the three bolts securing the camshaft drive belt front cover and remove it.

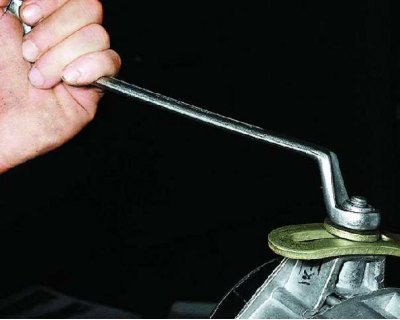

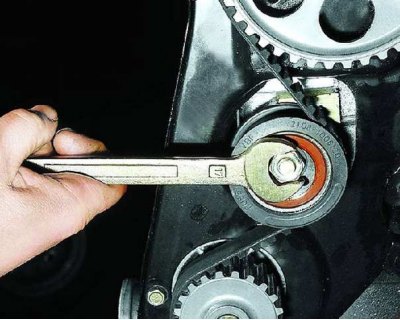

41. Turn away a nut of fastening of a tension roller.

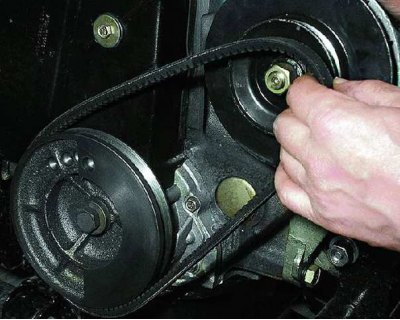

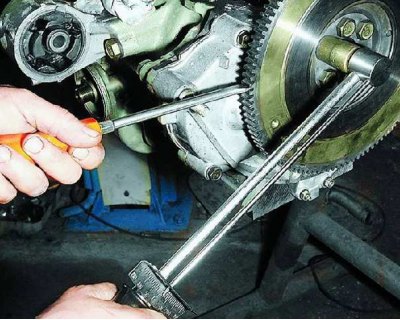

42. Unscrew the bolt securing the alternator drive pulley from the crankshaft, securing the flywheel from turning (rest a screwdriver in the bolt securing the clutch housing to the engine and in the flywheel ring gear). Remove the pulley bolt with flat washer.

43. Carefully pry with a screwdriver (or mounting spatula) alternator drive pulley and remove it from the front end of the crankshaft.

44. Remove the camshaft timing belt from the crankshaft pulley.

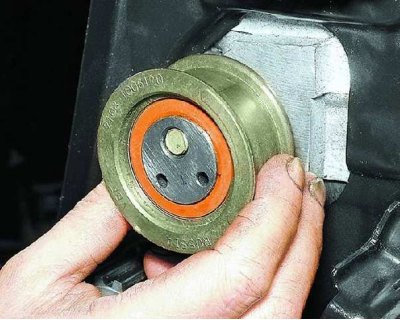

45. Remove the tension roller from the cylinder block stud.

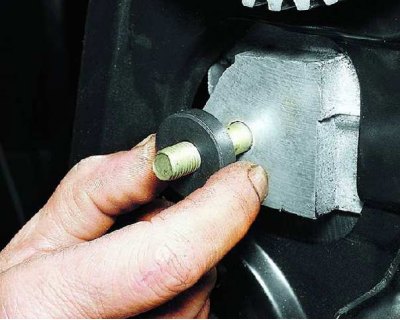

46. Remove the idler pulley spacer.

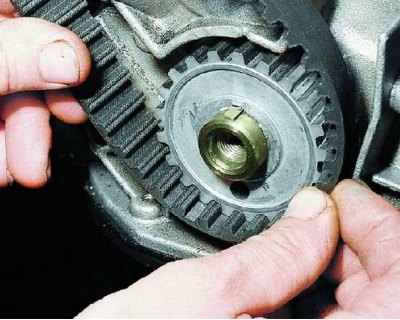

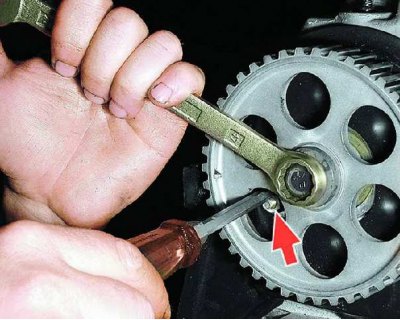

47. Secure the camshaft pulley against turning by resting a screwdriver on the stud securing the toothed belt cover, and unscrew the pulley mounting bolt.

48. Remove the camshaft pulley, remove the pulley key if it is loose in the shaft groove.

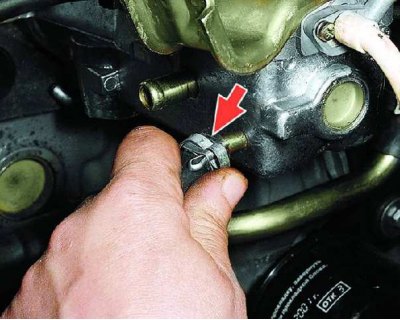

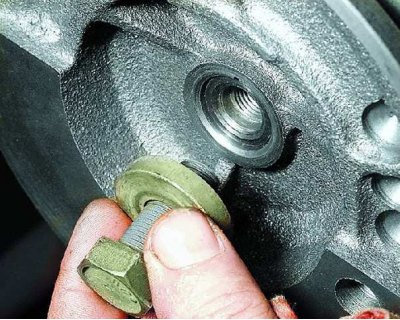

49. Loosen the nut and...

50....four rear cover bolts (three of them attach the water pump to the cylinder block).

51. Remove the rear camshaft drive belt cover.

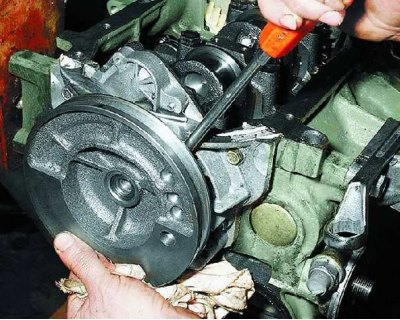

52. Insert a screwdriver between the pump housing flange and the block, slide the pump out of its seat.

53. Remove pump and gasket (shown by arrow).

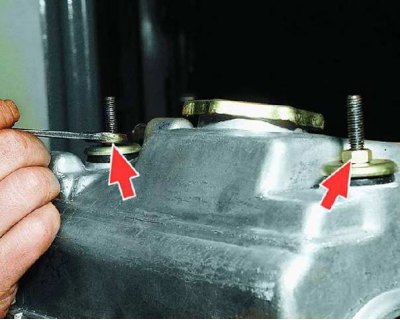

54. Remove the two nuts securing the cylinder head cover, remove the flat washers and...

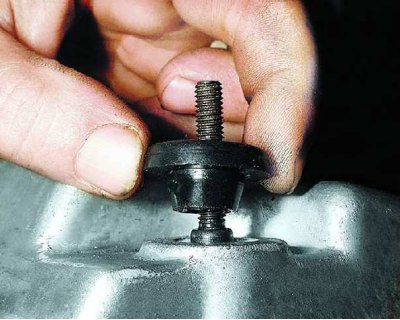

55....rubber bushings.

56. Remove the cylinder head cover.

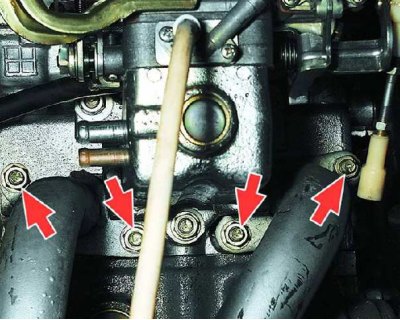

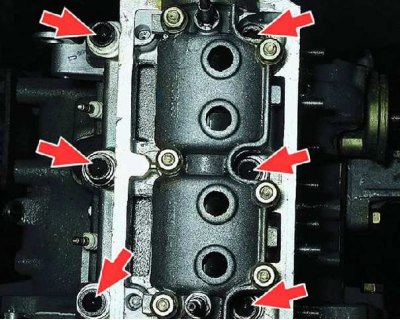

57. Loosen the six cylinder head bolts...

58....with an interchangeable socket, an Allen key and a torque wrench (since the tightening torque of the bolts is about 80 N/m or 8 kgf/m).

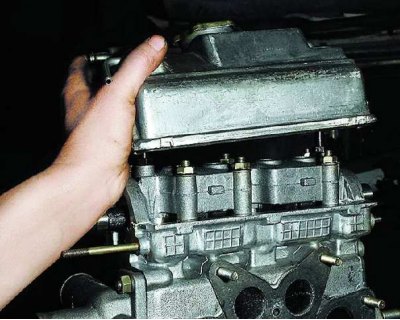

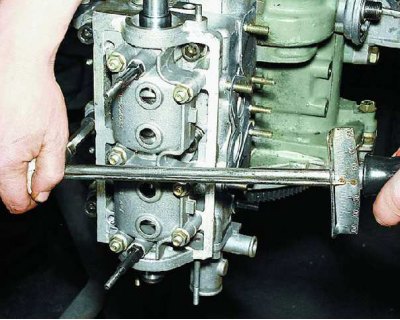

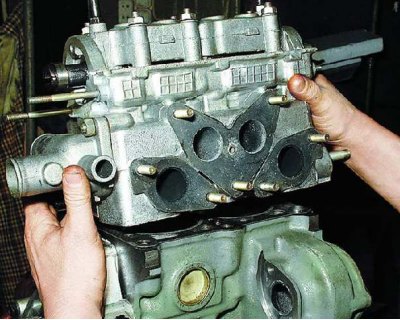

59. Using a screwdriver, separate the head from the block and...

60.... remove the cylinder head.

61. Remove the cylinder head gasket.

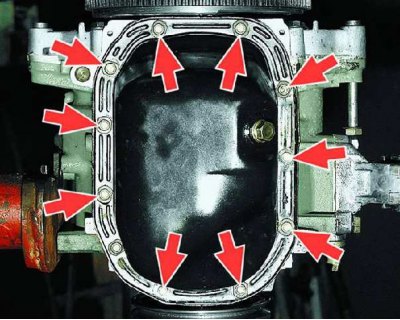

62. Remove the eleven bolts securing the engine oil sump.

63. Using a screwdriver, separate the oil sump from the cylinder block and remove the crankcase and its gasket.

64. Remove the three bolts securing the oil pump receiver (spring washers are installed under the bolt heads) and remove the receiver.

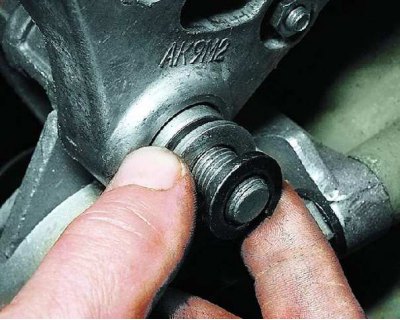

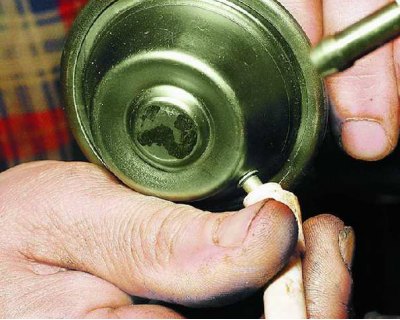

65. Remove the O-ring from the oil pump receiver.

66. Loosen the four nuts securing the lower connecting rod caps (two on each lid).

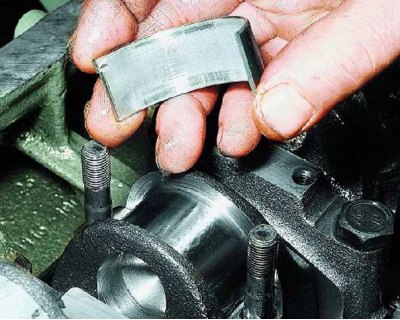

67. Remove the connecting rod bearing caps. If the cylinder numbers are not visible on them, mark (punching or paint).

68. Remove the connecting rod bearing shells from the crankshaft journals. If you do not plan to replace the liners, mark them on the non-working side.

69. Carefully push the connecting rods into the cylinders so that the connecting rods do not touch the cylinder walls.

70. Remove the pistons and connecting rods from the cylinders. If the cylinder numbers on the connecting rods are not visible, mark (punching or paint).

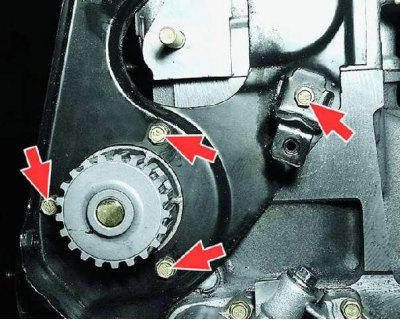

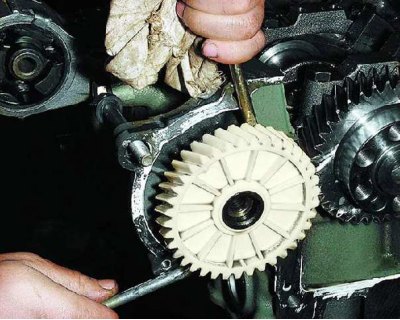

71. Pry off the crankshaft sprocket with a screwdriver and...

72.... remove it from the front end of the crankshaft.

73. Remove the toothed pulley key from the groove in the front end of the crankshaft.

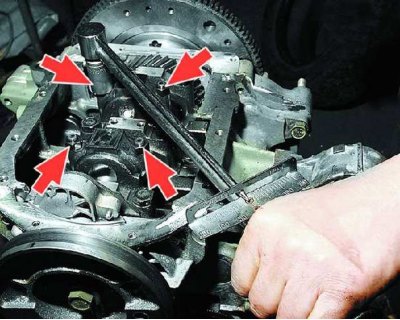

74. Loosen the six oil pump mounting bolts...

75.... pry it off with a screwdriver and separate the pump from the cylinder block.

76. Remove the oil pump assembly from the front end of the crankshaft.

77. Fix the flywheel from turning, unscrew the six bolts of its fastening and...

78.... remove the lock washer of the bolts.

79. Remove the flywheel from the rear flange of the engine crankshaft.

80. Please note: if the mounting sleeve remains in the flywheel, immediately mark the hole in the crankshaft in which it was installed. Otherwise there will be an imbalance.

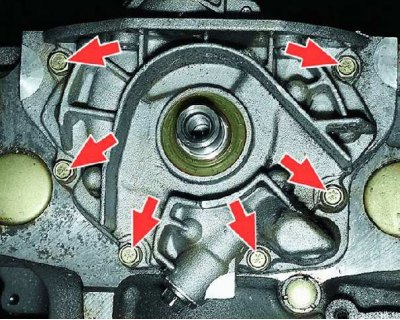

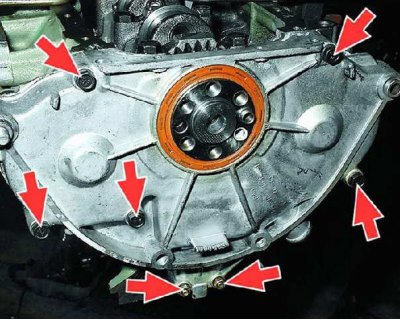

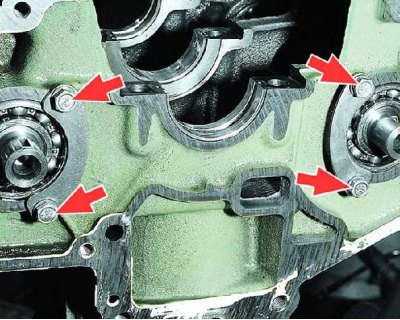

81. Remove the five bolts and two nuts securing the crankshaft rear oil seal holder.

82. Pry off the holder with a screwdriver and...

83....remove it from the engine.

84. Fix the crankshaft from turning by inserting a metal rod or pin into the balancing hole of its counterweight, and unscrew the bolts securing the gears of the balancing shafts.

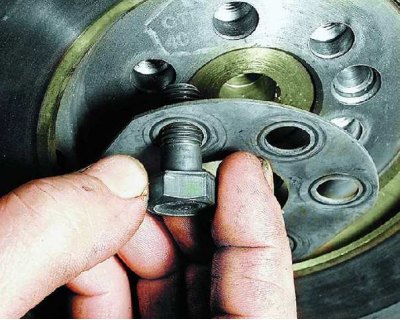

85. Remove bolts with flat washers.

86. Pry off the balance shaft gears with two screwdrivers and...

87....remove them from the shafts.

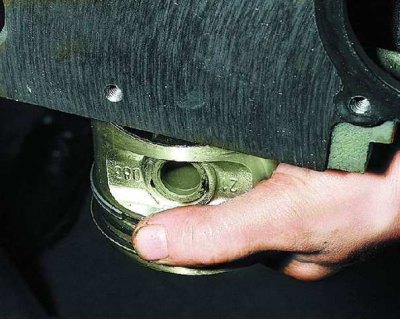

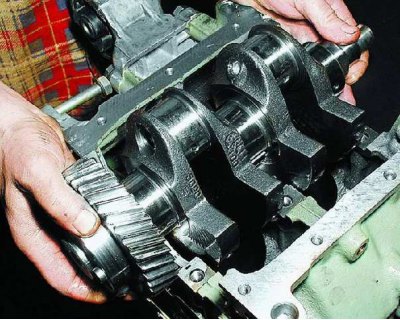

88. Loosen the six crankshaft main bearing cap bolts (two bolts on each cover) And...

89.... remove the main bearing caps and lower bearings.

90. Take out a cranked shaft from beds of the block of cylinders.

91. Remove the crankshaft thrust washers (on the middle main bearing of the crankshaft) and upper main bearing shells.

92. If necessary, remove the keys from the rear ends of the balance shafts.

93. If it is necessary to replace the rear bearings of the balancing shafts, unscrew the bolts securing the thrust plates and...

94....remove the plates.

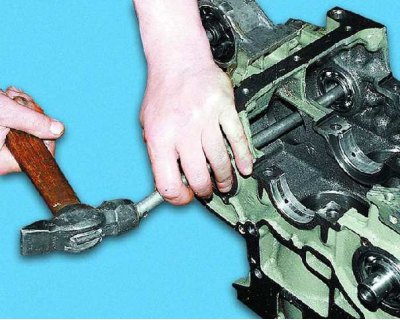

95. Knock the rear shaft bearings out of the cylinder block seats by hitting the balance shafts through a soft metal mandrel, and...

96.... remove the rear bearings of the balancing shafts.

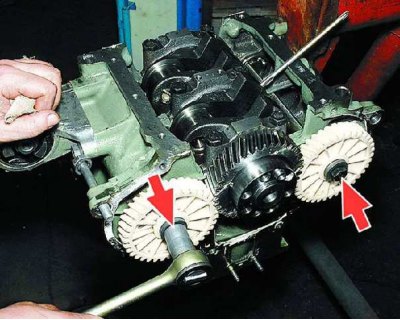

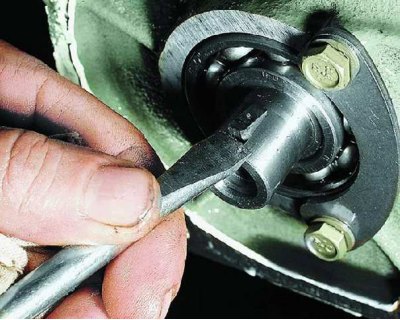

97. If it is necessary to replace the front bearings, remove the balance shafts. To do this, remove the retaining rings of the rear bearings using special pliers...

98....remove the balance shafts from the cylinder block through the rear bearing housings...

99.... knock out the plugs of the front ends of the balance shafts, remove the circlips and press out the front bearings with a drift (goatee), applying force to the outer rings of the bearings.

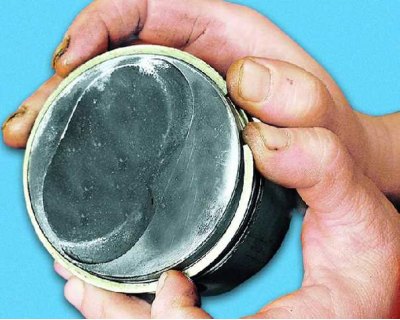

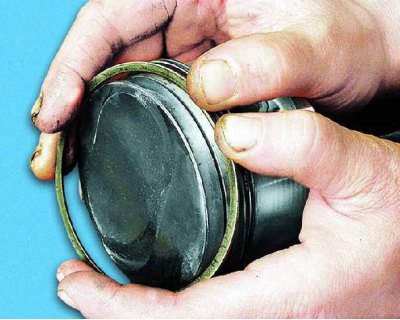

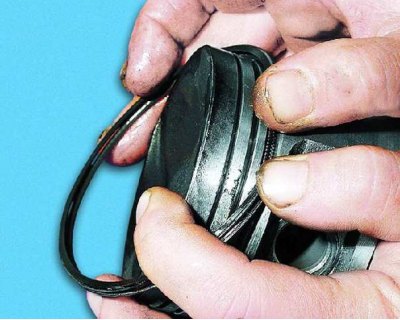

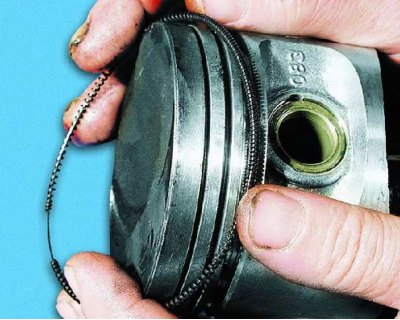

100. We recommend removing the piston rings with a special puller. If it is not there, gently release the lock of the upper compression ring and remove it from the piston.

101. Remove the lower compression ring in the same way...

102....oil scraper rings (top and bottom) And...

103.... oil scraper expander.

104. If necessary, use a special mandrel to press the pin out of the connecting rod. Please note that in order to assemble the piston with the connecting rod, it is necessary to heat the upper head of the connecting rod to a temperature of 240°C and a special mandrel is needed to install the piston pin.

105. Press the crankshaft rear oil seal out of the holder, placing bars under the holder so as not to damage it. Clean the mating surface of the holder to the cylinder block from the remnants of the old sealant.