- keys "for 8" And "on 10"

- screwdriver

Remove the fuel pump (see subsection 10.10.3.).

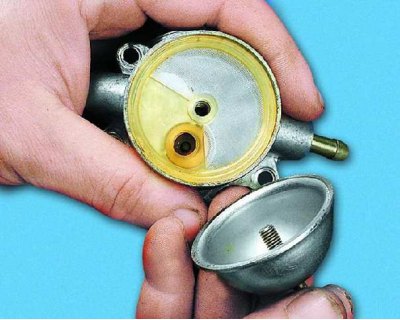

Recommendation. Before dismantling the pump, check the tightness of its valves. To do this, swing the lever of the manual drive of the fuel pump, alternately closing the suction and delivery (on the picture) finger fittings. A vacuum must be created in the suction valve, and pressure in the discharge valve (see subsection 10.10.2., operation 4).

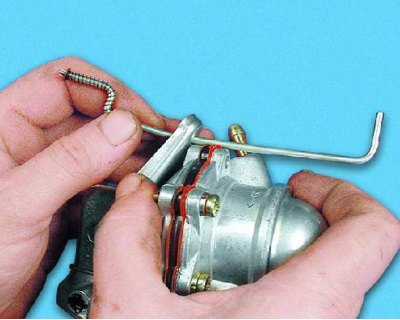

1. Loosen the screw and...

2....remove the tie rod bracket.

3. Remove the manual priming lever linkage by pulling it out of the hole in the lever.

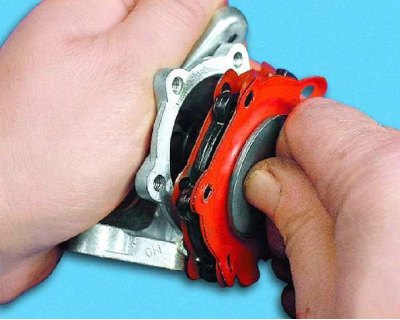

4. Loosen the remaining five mounting screws and...

5....separate the casing and the bottom cover of the pump.

6. Remove the diaphragm assembly from the bottom cover and...

7.... a spring.

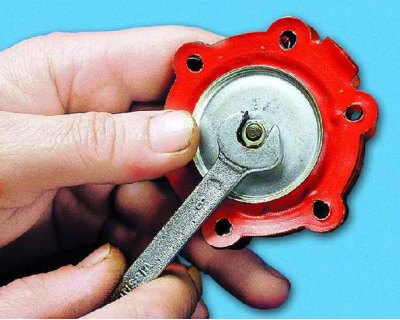

8. Replace torn, worn, or hardened diaphragms. For this...

9.... unscrew the fastening nut and...

10.... disassemble the diaphragm assembly. Assemble the diaphragm assembly with new diaphragms in the reverse order of disassembly.

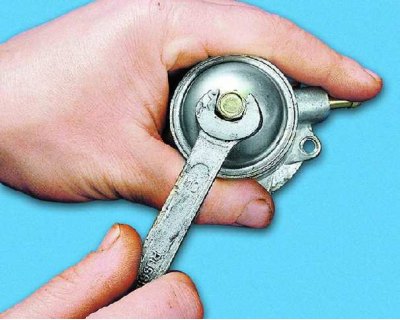

11. Loosen the nut and...

12....remove the top cover of the pump.

13. Replace torn or damaged strainer.

14. If the suction or discharge fitting is loose in the pump housing, replace the housing.

15. Replace body parts with cracks and chips.

16. The pump valves must work without jamming and be tight. Replace pump bottom cover with defective valves or only valves. To replace a valve...

17.... press it out after removing the punching. After pressing in the new valve, screw its seat in three places.

18. Rinse with gasoline and blow out all parts with compressed air. Assemble the fuel pump in the reverse order of removal. The diaphragm spacer has holes to drain fuel in the event of a diaphragm failure. When assembling, install the diaphragm assembly so that the holes on its gasket are located as far as possible from the exhaust pipe of the muffler.