- key "at 13"

- screwdriver

- hammer

Remove the gearbox (see subsection 11.1.1.).

The reasons for incomplete disengagement of the clutch can be:

- warping of the driven and pressure disks;

- breakage of friction linings or weakening of the rivets of the driven disk;

- jamming of the hub of the driven disk on the splines of the input shaft of the gearbox.

The reasons for incomplete engagement of the clutch may be:

- increased wear or oiling of the friction linings of the driven disk;

- oiling of the working surfaces of the flywheel and pressure plate.

Jerks during clutch operation can be caused by oiling of the friction linings of the driven disk, the working surfaces of the flywheel and pressure plate, or warping of the pressure plate.

Broken disc damper springs cause increased noise when the clutch is engaged.

1. Install the mandrel in the pressure plate hole.

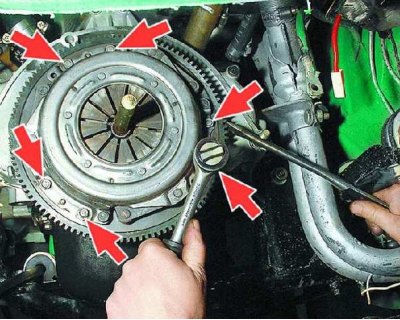

2. Lock the flywheel with a screwdriver from turning and unscrew the six bolts securing the clutch cover.

3. Please note that there is a spring washer under the head of each bolt.

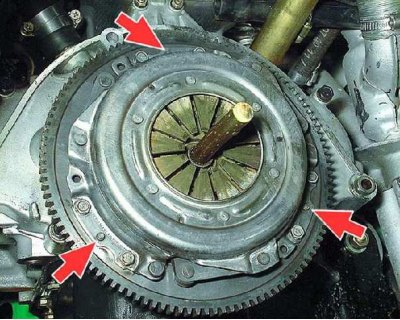

4. Remove the clutch cover assembly with pressure and driven discs. Hold the driven disk while doing this, otherwise it may fall out.

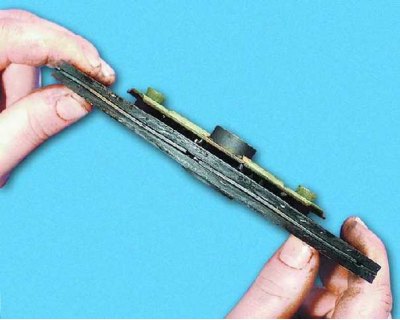

5. Cracks on the details of the driven disk are not allowed. Check the condition and wear of the friction linings 1. If the heads of the rivets 2 are less than 0.2 mm deep, the surface of the friction linings is oily or the rivet connections are loose, then the driven disk must be replaced.

6. Check up reliability of fixing of damper springs in nests of a nave of a conducted disk, at the broken springs the disk needs to be replaced.

7. Check up beating of a conducted disk if during visual survey its warping is found out. If the runout is greater than 0.5 mm, replace the disc.

8. Inspect the working friction surfaces of the flywheel and pressure plate, paying attention to the possible appearance of deep scratches, scoring, nicks, obvious signs of wear and overheating. Replace defective units.

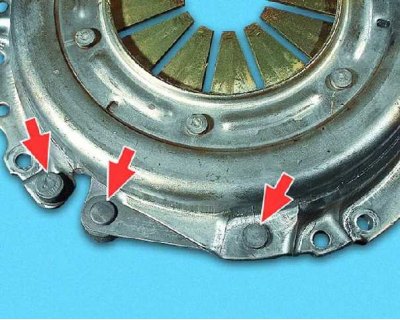

9. Visually evaluate the condition of the casing and pressure plate parts; replace them as an assembly if: loosening of rivet connections of casing parts...

10.... cracks in the diaphragm spring...

11....cracks and signs of wear on the compression spring support rings...

12.... misalignment of the spring petals (the contact points of the spring petals with the clutch release bearing must be in the same plane) and excessive wear at the points of contact with the bearing (wear should not exceed 0.8 mm).

13. Before installing the clutch, check the ease of movement of the driven disk along the splines of the input shaft of the gearbox. If necessary, remove the causes of seizing or replace defective parts.

14. Please note that when installing the driven disk, the more protruding part of its hub must be directed towards the pressure spring.

15. Insert the centering mandrel into the splines of the driven disc from the pressure spring side.

16. Install the clutch onto the flywheel using the three dowel pins (shown by arrows) and tighten the six clutch-to-flywheel bolts evenly in a criss-cross pattern, keeping the flywheel from turning. Remove the centering mandrel and install the gearbox.